Low Pressure Moulding

"We encapsulate the assemblies in plastic via low pressure moulding. This is a fast and cost-effective alternative to conventional encapsulation or potting."

"We encapsulate the assemblies in plastic via low pressure moulding. This is a fast and cost-effective alternative to conventional encapsulation or potting."

The electronic-assemblies that go into our product enclosure kits often include sensitive components. PCBs, sensors, and antennas may require additional protection from moisture, vibration and other challenging environmental conditions. To achieve this we encapsulate the assemblies in plastic via low pressure moulding. This is a fast and cost-effective alternative to conventional encapsulation or potting.

We also polish and finish raw-parts to produce aesthetically-pleasing products/components at budget-cost with minimal investment.

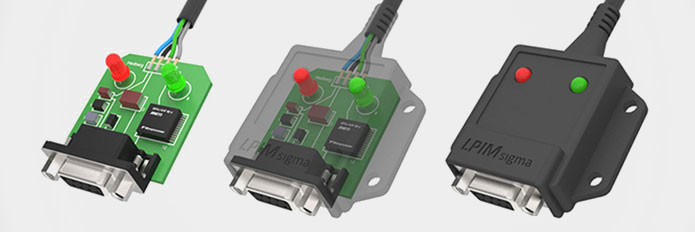

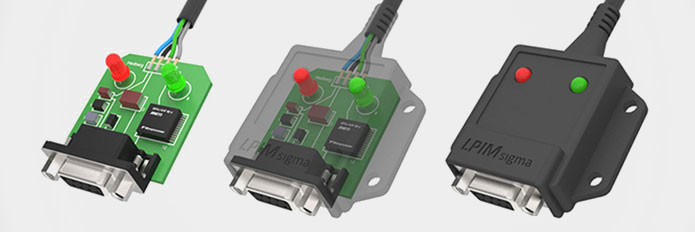

Low Pressure Over Moulded - Electronic Discharge Tool

Low Pressure Over Moulded - Connectors

Low Pressure Over Moulded Electronics