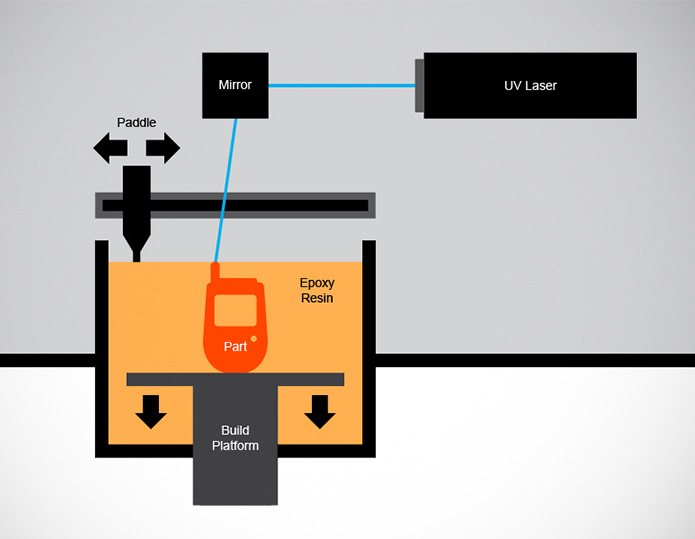

SLA

"Stereolithography is a rapid prototyping/additive layer manufacturing processes that uses a UV laser to cure an epoxy resin."

"Stereolithography is a rapid prototyping/additive layer manufacturing processes that uses a UV laser to cure an epoxy resin."

Stereolithography is a rapid prototyping/additive layer manufacturing processes that uses a UV laser to cure an epoxy resin.

The laser is directed by a computer controlled mirror. When the laser makes contact with the surface of the UV-sensitive epoxy resin it instantly solidifies. After a layer is applied, the build platform submerses in increments of 0.1mm. With each increment, a paddle sweeps across the surface of the resin to control layer thickness. Layer by layer the part is built below the surface, supported by a honeycomb structure (build strata).

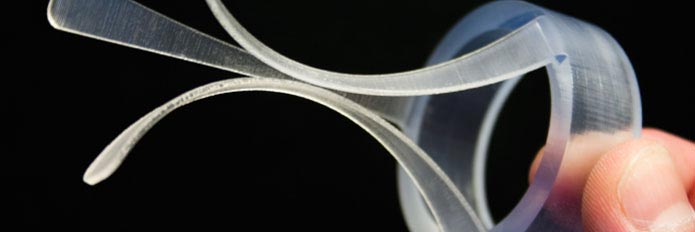

The built part is washed with isopropyl to remove any uncured resin and fully cured under an intensive UV light.