SLS

"Selective Laser Sintering is a rapid prototyping, or additive layer manufacturing process."

"Selective Laser Sintering is a rapid prototyping, or additive layer manufacturing process."

Selective Laser Sintering is a rapid prototyping, or additive layer manufacturing process.

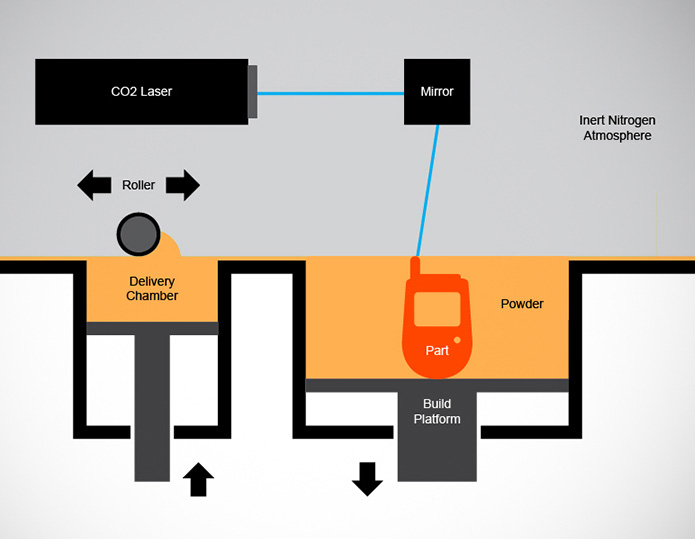

A CO2 laser is used to fuse a fine nylon powder. The laser is directed by a computer controlled mirror. When the laser makes contact with the nylon powder the surface particles are instantly fused to form a solid. After a layer is fused, the build platform moves downwards 0.1mm. Each time the platform moves downward, rollers spread a fresh layer of powder across the build platform. Layer by layer the solid part is built.

The process takes place within a temperature-controlled chamber with an inert nitrogen atmosphere. This prevents the nylon from oxidizing under the laser. The process is slow but cost-effective, as it requires no tooling or jigging.